The beautiful textiles made by the likes of Kirin & Co., Pippijoe, and Mod Green Pod are inspiring and beautiful, but they carry a designer price tag. If you can’t afford designer hand-printed fabrics, consider screen printing your own. By printing your own fabric you can control the materials used, the design, and colors.

Learn to Screen Print

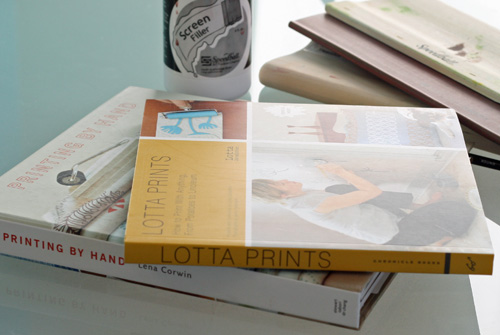

I recommend reading up on screen printing before you get started. While most hand printing methods seem overwhelming to a beginner, they are all quite easy to perfect with a little patience and practice. I highly recommend reading Lotta Prints by Lotta Jansdotter and Printing By Hand by Lena Corwin. Both of these books provide a thorough overview and how-to for each of the hand-printing methods. Each book also includes a few patterns from the author. Anna Laura, of the blog Anna Laura Art, shares a wonderfully detailed how-to for screen-printing with drawing fluid and screen filler.

Finding Base Cloth

Once you have read about screen printing and you are ready to try your own, you will need to find base cloth suitable for printing. First consider re-using fabric you already have. You can use material from bed sheets, curtains, flour sack dish towels, or tablecloths. If you need to buy fabric, Mod Green Pod offers organic cotton canvas for $15/yard (it is the same base cloth they use for their beautiful prints). Near Sea Naturals has a great selection of organic cotton and hemp fabrics suitable for printing. Start by searching for canvas.

Basic Supplies

Most art supply stores carry all the basic supplies for screen printing. You will need a screen, drawing fluid, screen filler, paint brushes, a squeegee, and ink (see more below). The screen and drawing fluid/screen filler can be expensive. For a cheap alternative check out the Cheap Screen Printing Tutorial for an alternative using an embroidery hoop, sheer fabric, and Mod Podge.

The Right Ink

The final piece of the puzzle is the right ink. The most eco-friendly inks are water-based and non-toxic. The brand I personally use is Permaset Aqua by Colormaker. Their site explains the environmental benefits best. In addition to printing on fabric, the Permaset Aqua inks can be used to print on other surfaces like paper and wood. Learn more about inks and get answers to the most frequently asked questions on the Permaset Aqua Blog. Permaset Aqua inks do not contain ozone-depleting chemicals such as CFC’s and HCFC’s, aromatic hydrocarbons or any volatile solvents. And you don’t need solvents to clean the screens down after they’ve been used – you can clean them with water.

Re-Use and Minimize Waste

To be truly eco-friendly, you should strive to re-use materials and minimize waste as much as possible during the printing process. By printing your own fabric you are automatically minimizing waste, because your can print exactly the amount of fabric you need. After printing scoop excess ink back into a container for future use. I use old baby food jars to mix test colors and store small amounts of ink. When you are done using a particular design, the screen filler can be removed and the screen can then be re-used for a new design.